-

PACKAGING SOLUTIONSAutomatic or semi-automatic filling and packaging machines.

PACKAGING SOLUTIONSAutomatic or semi-automatic filling and packaging machines.

Our mission is to improve the performance and competitiveness of our clients, creating solutions that meet their ambitions and ambitions, providing a quality service based on competence and an out of the box vision of our employees.

The project design is essential for the manufacture of machines for bag-in-box (BIB) packaging products.

Whatever the model, our team is highly skilled.

We have a team of highly specialized mechanical fitters in the art of treating machines.

Their work is immediately recognized as excellent by presentation and care.

Our service goes beyond the machine we deliver to the customer. Our services and support are constant, and we bet on a highly effective after sales service.

FILLING METHOD

Through a metering valve, controlled by the flow meter.

FILLING

Prepared for filling bags from 1 to 20 liters.

LIQUIDS THAT CAN BE FILLED

Agricultural chemicals

Wine and other alcoholic beverages

Automotive fluids - Oil

Cleaning products

Coffee and tea

Oil

Juice

Water

MAINTENANCE / CLEANING

Ideally, maintenance should be done once per year, namely hoses,

seals, and gaskets.

Cleaning (Purge / CIP) must be done before and after the filling.

MAIN FEATURES

One of the great advantages of the SOLUFILL 100 is its portability

and reduced size, although it is manual equipment for filling in

Bag-in-Box © (BIB) system that only needs one operator.

For better conservation of the product, at the beginning of the filling,

it uses a vacuum system and, in the end, nitrogen injection.

FILLING METHOD

Through a dosing valve, controlled by the flowmeter.

FILLING

Prepared for filling bags from 1 to 20 liters.

LIQUIDS THAT CAN BE FILLED

Agricultural chemicals

Wine and other alcoholic beverages

Automotive fluids - Oil

Cleaning products

Coffee and tea

Oil

Juice

Water

MAINTENANCE / CLEANING

Ideally, maintenance should be done once per year,

namely hoses, seals, and gaskets.

Cleaning (Purge / CIP) must be done before and

after the filling.

MAIN FEATURES

One of the great advantages of the SOLUFILL 200 is its reduced size,

although it is semiautomatic equipment for filling in Bag-in-Box© (BIB)

a system that only needs one operator.

For better conservation of the product, at the beginning of the

filling it uses a vacuum system and, in the end, nitrogen injection.

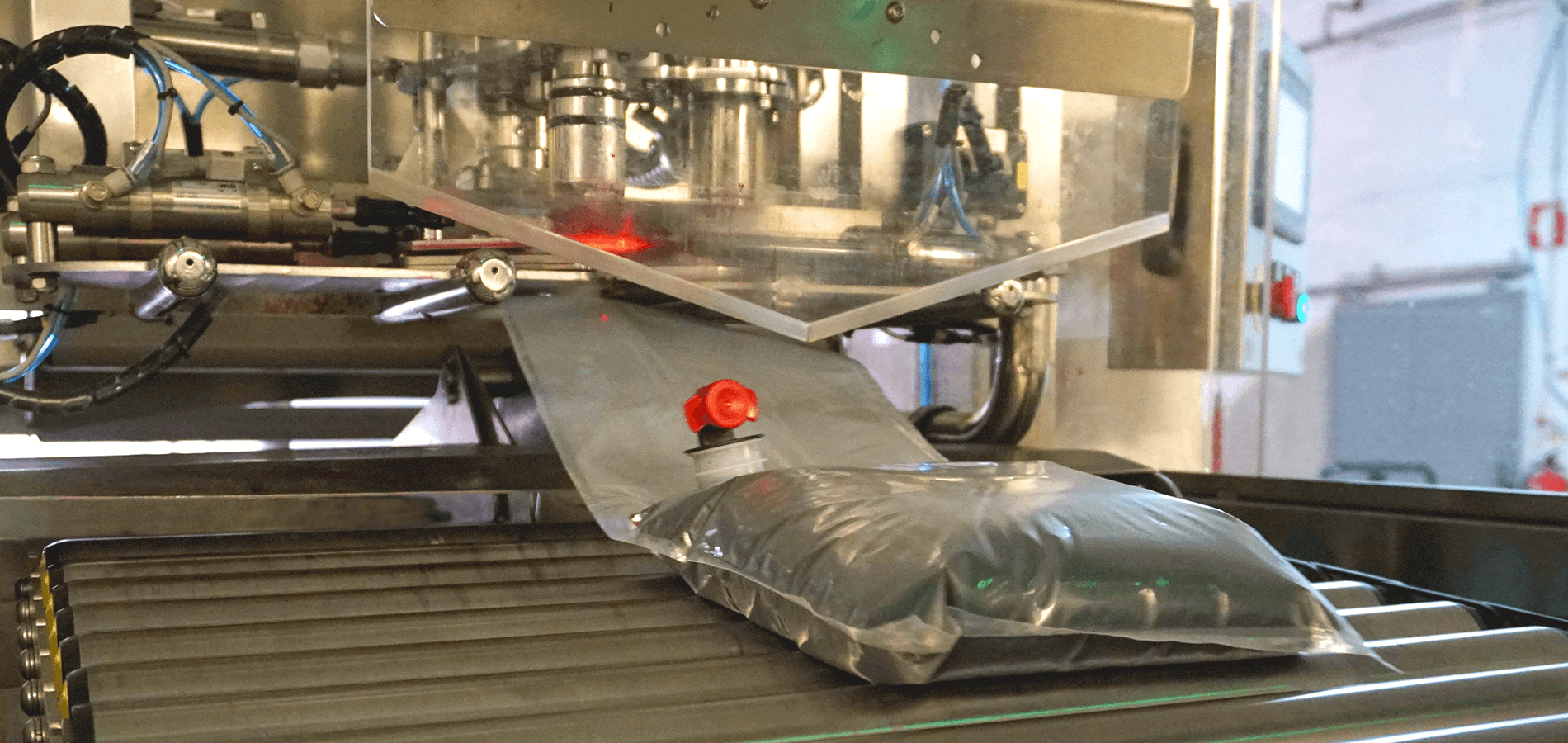

FILLING METHOD

Through a dosing valve, controlled by the flowmeter.

FILLING

Prepared for filling bags from 1 to 20 liters.

LIQUIDS THAT CAN BE FILLED

Agricultural chemicals

Wine and other alcoholic beverages

Automotive fluids - Oil

Cleaning products

Coffee and tea

Oil

Juice

Water

MAINTENANCE / CLEANING

Ideally, maintenance should be done once per year,

namely hoses, seals, and gaskets.

Cleaning (Purge / CIP) must be done before and

after the filling.

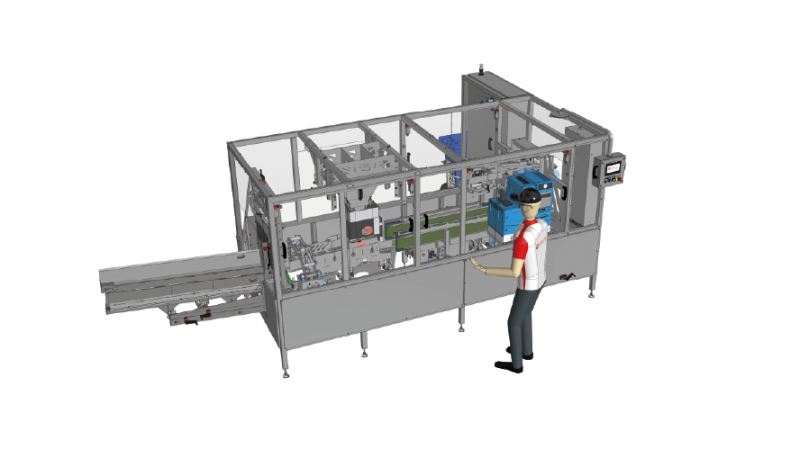

MAIN FEATURES

The SOLUFILL 400 is an automatic device for filling in a Bag-in-Box (BIB)©

a system that only needs one operator. Its great advantage is the filling volume

that allows and reduced time.

For better product conservation, at the beginning of the filling, it uses a

vacuum system and in the end, nitrogen injection.

FEATURES

Bag-in-Box© (BIB) forming equipment, assembled with

a 3-zone monoblock box forming, funnel, and box closing.

TYPE OF BOXES BY INDUSTRY

Agricultural chemicals

Wine and other alcoholic beverages

Automotive fluids - Oil

Cleaning products

Coffee and tea

Oil

Juice

Water

MAINTENANCE / CLEANING

Ideally, the maintenance should be carried out once a year,

in particular the belts and removable elements, as well as

the glue machine that needs an overhaul.

MAIN FEATURES

The SOLUFORM 100 was designed to work with boxes of 1 to 20 liters,

having been developed to minimize the cost of switching time between

different boxes (about 15 minutes).

Due to its compact design, it is extremely versatile and adapts to any layout.

Instead of the traditional rollers that are over the drying zone, we use a box presser

that reduces the stopping time for cleaning the equipment.

Solubag packaging technologies general catalogue and leaflets

List of customers with equipment and solutions installed by Solubag Packaging Tecnologies

Zona Industrial dos Pousos

2401-901 | Leiria, Portugal